Design, studies and industrialization of custom washers

Designing a custom spring washer requires a good knowledge of the product. Thanks to our experience and know-how, our Engineering & Design Department can work on all your projects and products by offering you solid technical expertise combining responsiveness, advice and proximity.

OVER 50 YEARS OF EXPERIENCE DEVELOPING THE TECHNOLOGIES OF TOMORROW

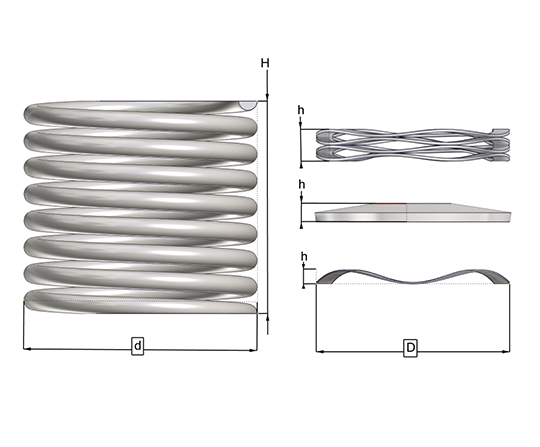

Small spring housing, extreme temperatures, specific environment; In terms of energy stored per material volume unit, spring washers are among the most effective type of springs. Whether for prototypes or large runs, our Engineering & Design Department can create all types of custom washers. We are constantly innovating and looking for new products, new geometries and new manufacturing processes.

WE CAN CREATE YOUR CUSTOM WASHER

Borrelly’s Engineering & Design Department has the expertise to help you resolve your technical challenges by creating your own custom washer.

A RENOWNED EXPERTISE IN THE DESIGN AND MANUFACTURE OF CUSTOM WASHERS

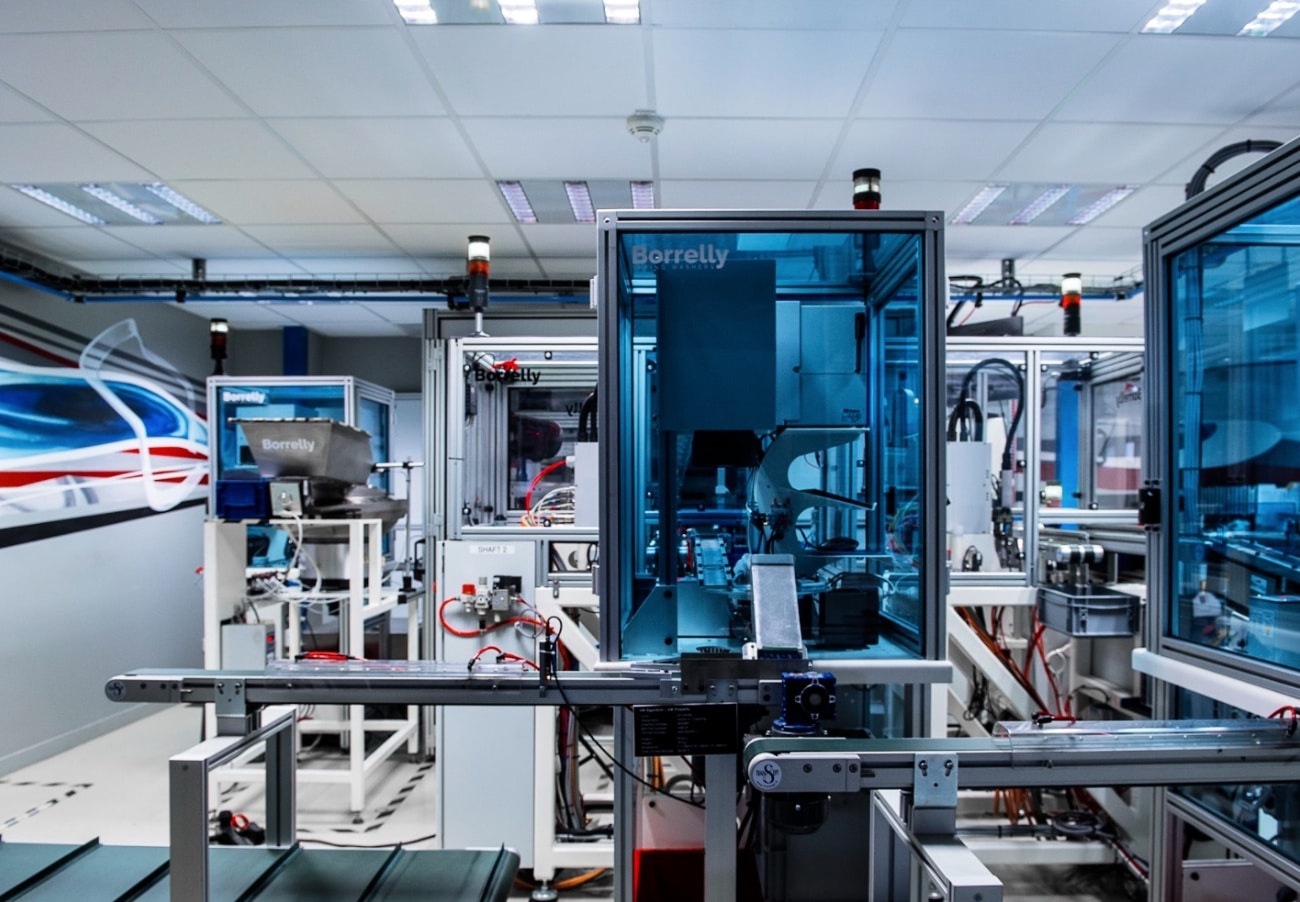

For over 50 years, our Engineering & Design Department has been providing a full range of services related to highly technical spring washers (design, development, materials, industrialisation).

We can provide you with these solutions based on our know-how in mechanical calculations and finite element studies.

Our ability to find solutions and provide excellent manufacturing quality from prototypes to very large runs has been recognised by major players in sectors as varied as aeronautics, automotive, aerospace, defence, nuclear, motor sports, mechanical engineering, off-shore, medical and household appliances.

OVERCOME YOUR TECHNICAL CHALLENGES WITH YOUR OWN CUSTOM WASHER

Together, we can design the custom spring washer best suited to your needs:

- Smaller housings,

- Specific environments,

- Cryogenics – very high temperature,

- Static or dynamic fatigue

- Spring materials (common or super alloys),

- Development, testing,

- Prototypes and large runs

We assess your requirements with you and draft specifications to find the most technically and economically suitable solution. We study your work environment and adapt the material to meet the most severe constraints. We can very quickly manufacture prototypes to be tested statically, dynamically, etc…

Thanks to the use of high-performance software, tried, tested and improved for over 50 years, our qualified team is at your disposal from the Calculation phase on the finished element to the End Product. As a designer and manufacturer of custom washers, our main goal is to optimise the customisation process and to be your constant partner and providers of constantly-improved products.

Our flexibility and high-performance production equipment endow us with great capability and mean that we can meet your needs over a very wide range.

Among the custom washers we frequently manufacture are: wave washers, wave springs, diaphragm washers, Belleville disc springs, as well as optimized Belleville disc springs.

Our materials catalog

We have a very large stock of materials and can manufacture any type of spring washers in very short lead times.

Carbon steel, stainless steel, duplex, super duplex, beryllium copper, super alloy are among the most commonly used materials to manufacture our spring washers.

During the designing phase of your custom washer, our Engineering & Design Department will help you choose the material best suited to your requirement specifications.

CUSTOM DESIGN REQUEST

We study your needs to design your custom spring washers.