Borrelly Belleville Disc Springs

We specialize in the design and manufacture of Borrelly disc springs.

We can provide our customers with widely acknowledged know-how and a worldwide reputation in our field.

Our expertise in Belleville washers enabled us to solve even the most demanding problems for very high-tech sectors such as offshore, nuclear, petrochemical and aerospace.

We offer a standard range of DIN 2093 Belleville spring washers manufactured from carbon steel and work daily on prototypes or medium runs of exotic materials such as nickel alloy, titanium, composite or beryllium copper.

Our 90 years of expertise have enabled us to design and develop numerous ranges of high-quality technical standard products. Discover our wide range of references, generally available from stock.

Application sectors

- Oil and Gas

- Mechanical industry

- Motor Sports

- Consumer goods

Thanks to our experience and know-how, our in-house design office can solve the most demanding problems in high-tech sectors, from prototype to mass production.

Application sectors

- Defense

- Motor Sports

- Nuclear

- Mechanical industry

- Oil and Gas

- Consumer goods

- Aeronautics

- Aerospace

- Automotive

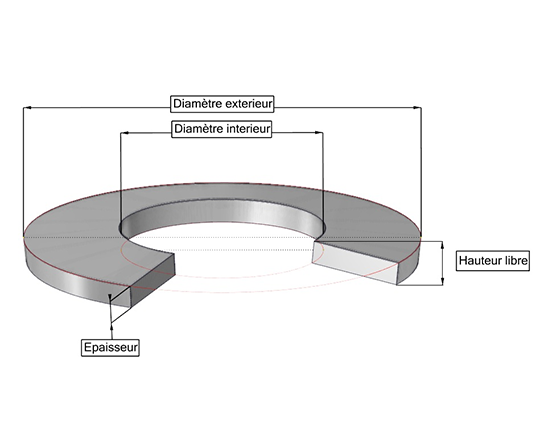

Technical description

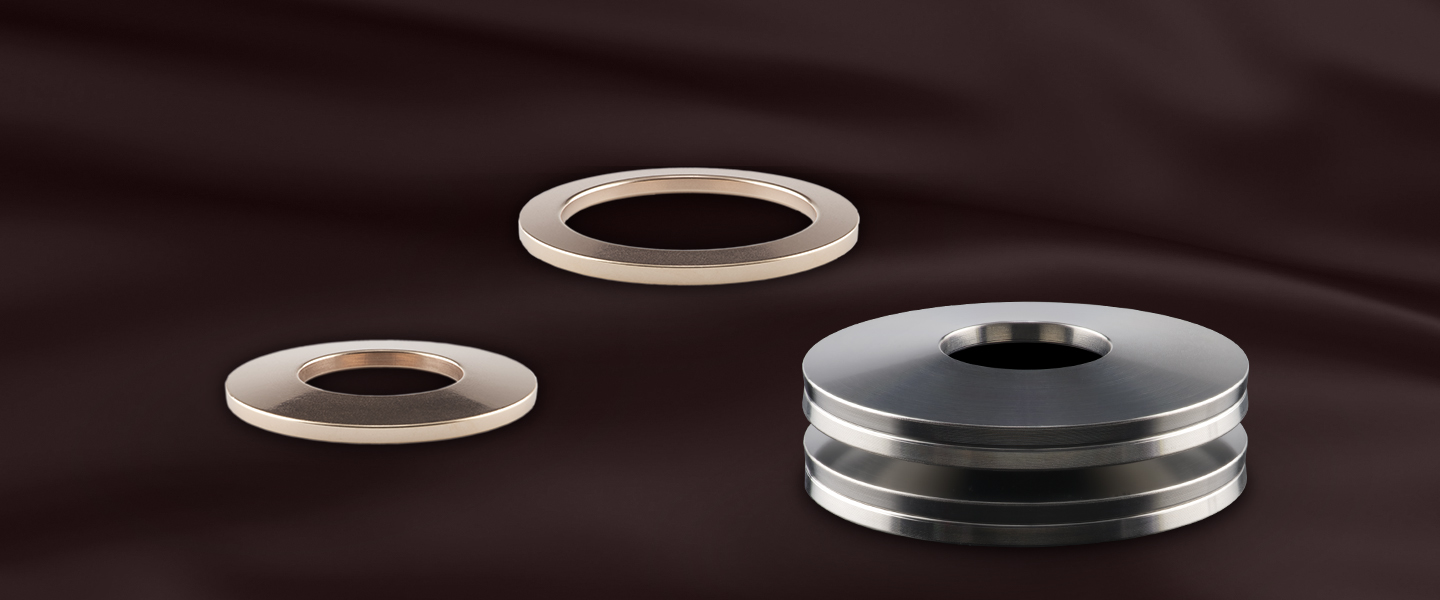

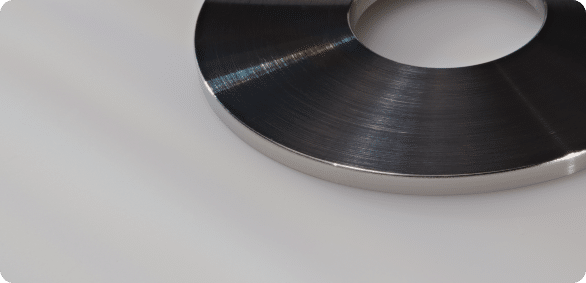

Belleville disc springs, also known as Belleville spring washers, are conical spring washers. They are designed to be axially loaded, either statically or dynamically.

This geometry enables high loads to be developed in a small space, so they are often used in assemblies requiring high stiffness. With excellent resistance to high stresses and strains, this type of washers is also highly capable of absorbing shocks and vibrations.

Our standard Belleville springs are manufactured in accordance with DIN 2093 specifications.

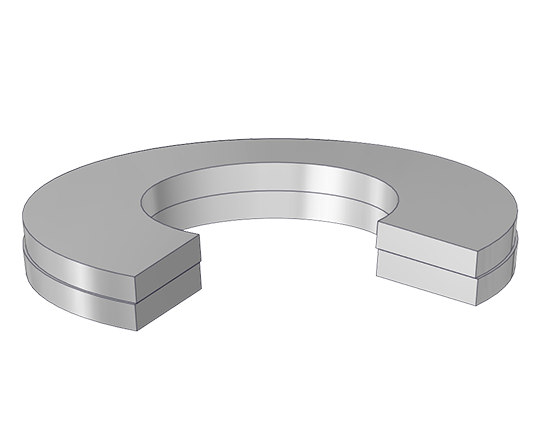

Belleville disc springs can be used singly and be centred either by the inside or outside diameter.

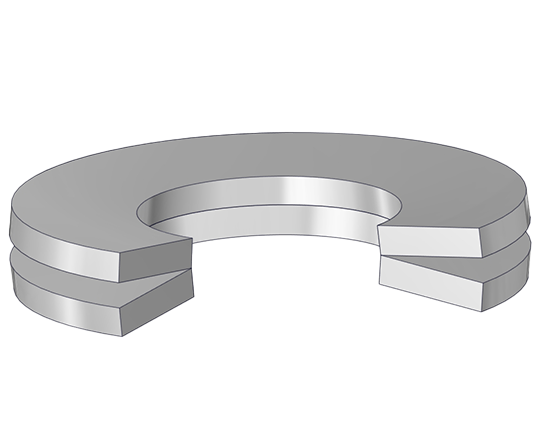

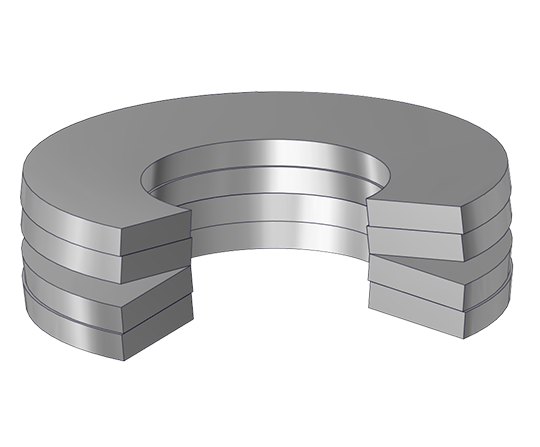

Belleville washers are frequently used stacked, either in the same direction (parallel stacking) or in alternating directions (serial stacking) as well as in combination (mixed stacking) according to the desired force-deflection characteristic. Depending on their configuration, the stacking’s stiffness will vary.

Serial stacking Belleville disc springs: the deflections are added, and the final force is equal to that of a single washer.

Parallel stacking of Belleville disc springs: the deflections are added, and the final deflection is equal to that of a single washer.

Mixed stacking of Belleville disc springs: serial stacking of disc springs, themselves made up of disc springs stacked in parallel

Empilage mixte de rondelles Belleville : empilage série de plusieurs groupes de rondelles, eux-mêmes constitués de rondelles empilées en parallèle

- Significant forces can be obtained

- A very broad range of elasticity curves can be generated

- High level of shock absorption in the case of parallel or mixed stacking

- Limitless stacking configurations

SAMPLE APPLICATIONS FOR Belleville disc springs

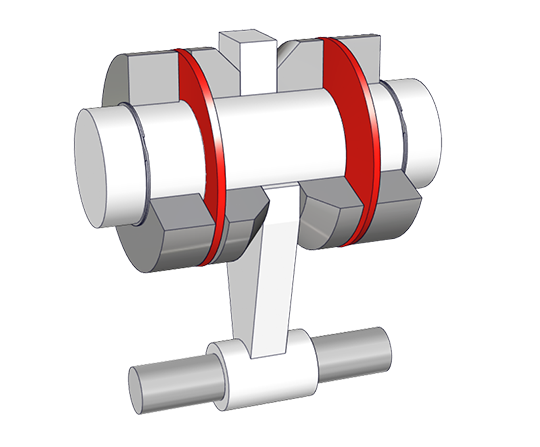

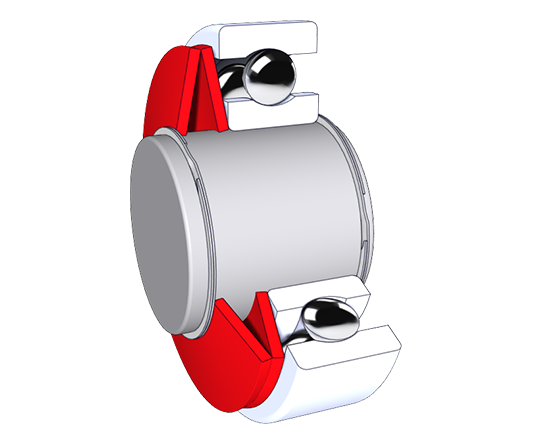

Belleville washers can be used for a variety of purposes: to solve problems of vibration, thermal expansion or relaxation, to maintain the load on a seal… They are commonly used in critical applications such as safety valves, clutch and brake mechanisms.

Belleville spring washers are perfectly suited for compression spring applications requiring large loads in small spaces. They can be used for a variety of purposes : to solve vibration, thermal expansion, or relaxation issues, to maintain load on a seal or a gasket… They are commonly used in critical applications such as safety valves, clutch and brake mechanisms as well as industrial pipe systems.

- Knife spring

- Pre-loading of ball bearings

CUSTOM Belleville disc springs

Thanks to its extensive experience and technical expertise, our Engineering & Design Department can help you in the design, engineering, and manufacturing of custom Belleville disc springs meeting your technical requirements. Your own custom Belleville washers can be made in a wide range of special alloys and finishes, including Inconel, Beryllium Copper and more.

We study your needs to design your custom spring washers.

Our other products

Borrelly Wave Washers

Custom-made

Borrelly Ondufil Wave Springs

Custom-made

Borrelly Belleville Disc Springs

Custom-made

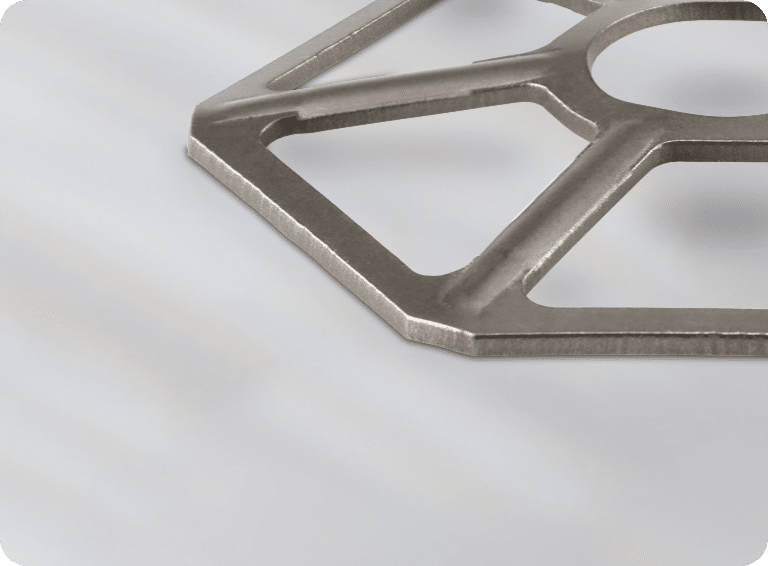

Borrelly Diaphragm Washers

Custom-made

Borrelly Rob : Optimized Belleville Disc Spring

Custom-made

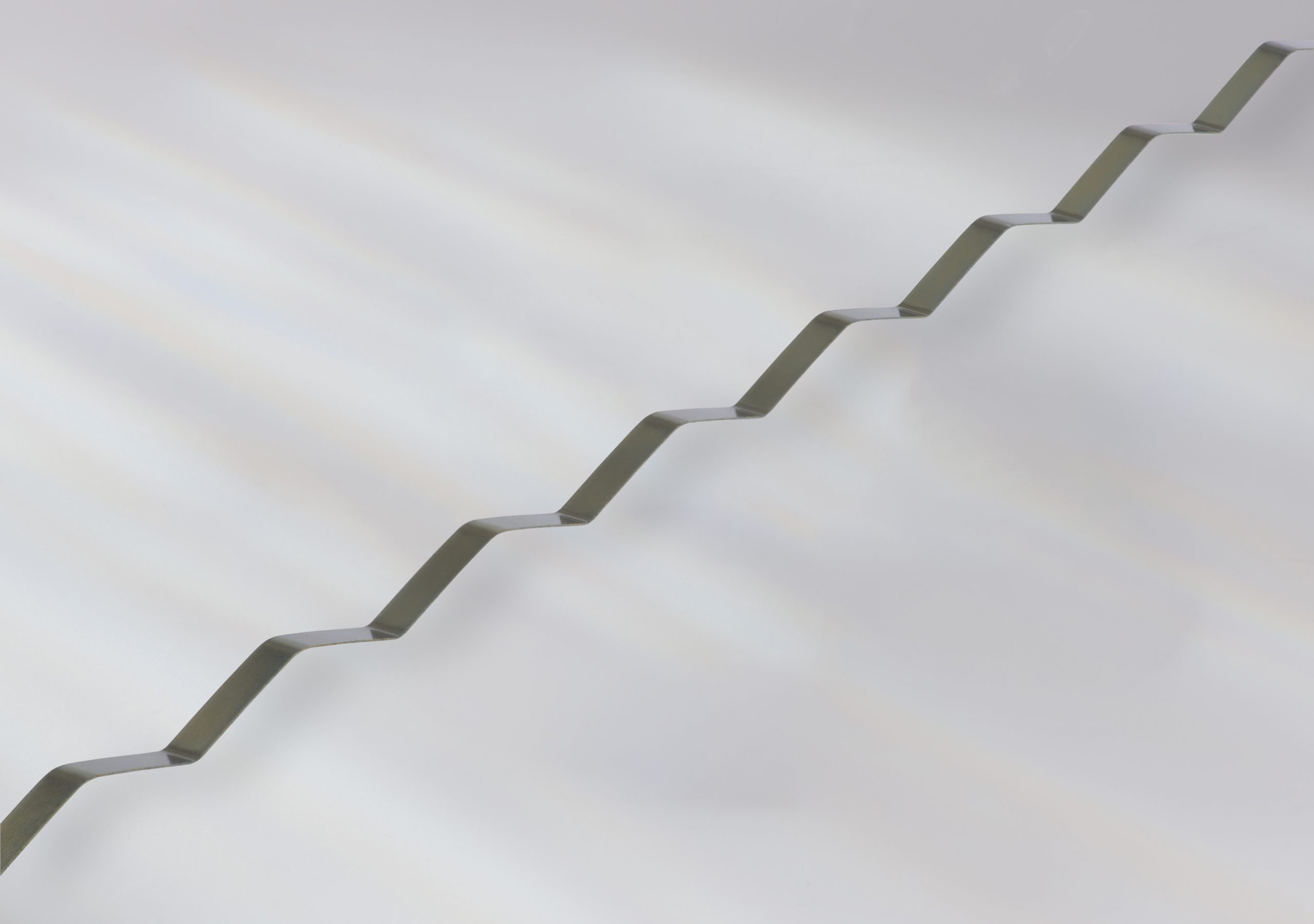

Borrelly Ribbon Springs

Custom-made

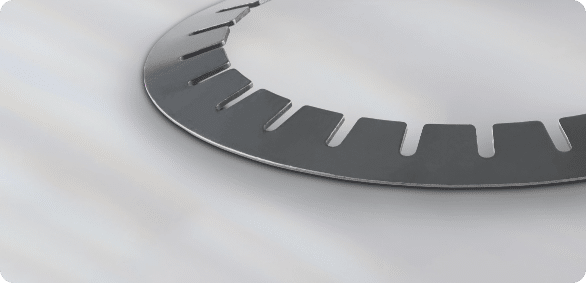

Borrelly 360 Spiral Retaining Rings

Custom-made

Borrelly Thin shim washers

Custom-made